In the process of introducing new products into the range category managers have to consider how much of a new product should be ordered to have it all sold before the replenishment. Most retailers are trying to calculate the demand in Excel. RETANO clients employ forecasting benefits of Retano SCM artificial intelligence.

Typical solution

The most common approach is to manually assign references to new products. References are used as examples of the sales model for the new product until enough data is gathered. Annual rotation sometimes exceeds 30% of range. This makes manual identification and adjustment of references too labor-intensive.

The retailer can teach the forecasting system to pick references for new products based on product attributes. For example, a good initial reference for the “milk” category can be found by searching products with the same price, volume, and inherent attributes. Attributes such as content of fat, lactose, and gluten. This approach has its disadvantages:

- The set of important product attributes can change over time. For example, at first, the taste of the product can be the decisive factor. Then, the manufacturer’s reputation and product composition can become more important. These changes should be regularly added to the logistic system manually. With the volume of several thousand products this process is difficult and expensive.

- For a high-quality forecast on one reference product, 13 months of sales history is needed. Not every reference product would have it.

Retano SCM automated ordering system can create high-quality forecasts for new products without relying on additional characteristics of reference products.

Retano SCM automated ordering system can create high-quality forecasts for new products without relying on additional characteristics of reference products.

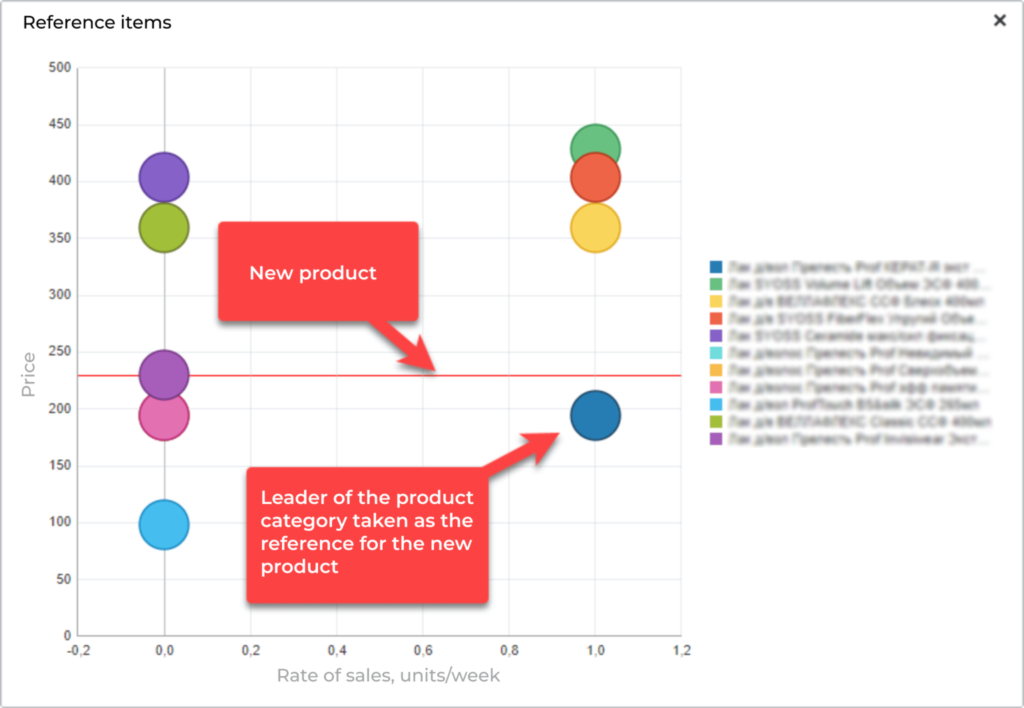

For “A” class products on ABC. New product category leaders don’t appear in the range often. For them, it is expedient to use forecasts based on the reference product. For convenient work with reference products Retano SCM has a graphic master where category managers can find a suitable reference for price and sales speed. In comparison with product characteristics, this data doesn’t need manual actualization.

Human involvement is only required for the stage of visual choice of the reference in the master. The system can process other stages on its own.

For “B” and “C” product categories. Presentation stock is calculated automatically based on the assigned size of the product display in the planogram. Then, the system forecasts demand based on the existing sales history. Seasonal and trend influences are taken from the data of the product group.

Retano SCM employs several forecasting methods. System’s artificial Intelligence independently chooses the most suitable method for the product group and specific circumstances. The user doesn’t have to think about the correct grouping of products and stores to identify seasonal changes and trends. The algorithm calculates all options and chooses the best. For perishable goods, this approach allows getting a high-quality forecast after 1-2 weeks of sales with no human involvement.