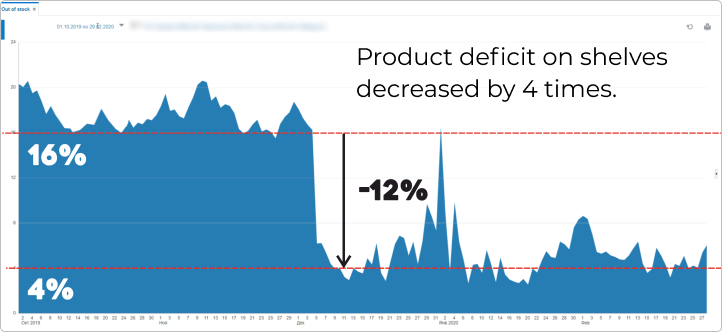

Most demanded products generate up to 80% of the retailer revenue. These products must always be present on shelves. Even one hour of product’s absence from the shelf leads to lost sales. Systematic Out-of-stock distorts sales statistics and leads to more errors in orders. That may lead to the gradual outflow of demanded products from the product range, loss of clients, and decrease in sales.

Retailer selling fresh and frozen products solved this issue by implementing Retano SCM. The retailer linked 150 stores, distribution center, and its own production facility to the automated order system.

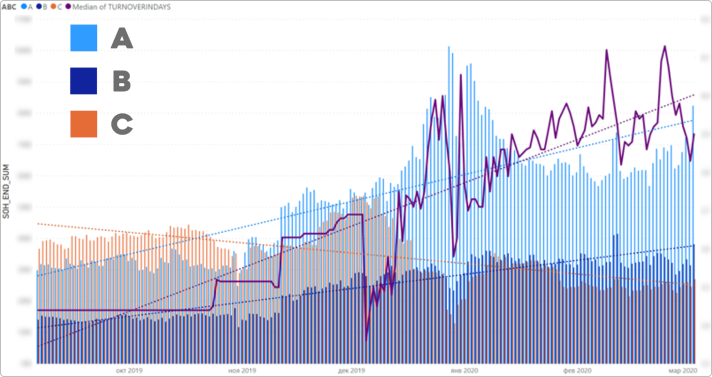

Retano SCM optimized retailer’s stock distribution

With manual orders, managers estimated demand on individual products incorrectly. With the manual ordering system the accuracy of orders suffered. Retano SCM replenishment started to increase the share of A and B products in orders based on demand forecasts.

The quality of store replenishment increased

Stock used to sustain 2,4 days of operation due to the small size of stores. Daily replenishments couldn’t ensure the product presence on shelves. The change in order structure decreased Out-of-Stock cases and increased stock to 3,5 days of operation.

Correct demand forecast made production planning better

Before Retano SCM implementation, product planning was not considering out-of-stock. The demand forecasting system cleaned sales history from OOS and other anomalies. Artificial intelligence chose the most optimal method for regular sales and promos forecasting. Retano SCM supported retailer’s transition to the demand driven supply chain, from production, through DCs, to stores.

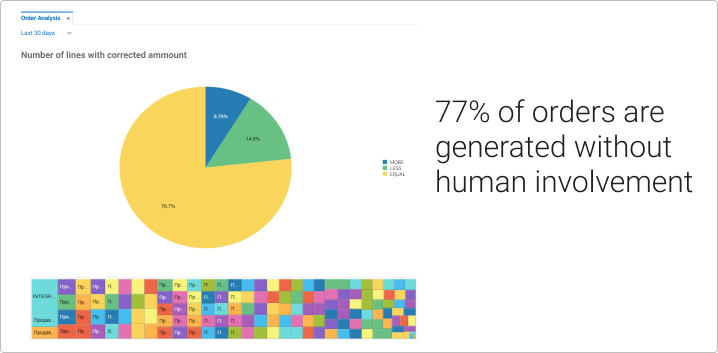

Retano SCM decreased labor costs for ordering

As the system forecasts and calculates orders faster and more accurately than a human can, only a fraction of orders, less than 23%, are left open for corrections to facilitate direct customer orders.