Retano SCM

Harness the power of Artificial Intelligence and Big Data technologies to optimize supply chain operations

Less Manual Work. More Profit.

Today’s retailers face a complex challenge: even minor supply chain hiccups lead to lost sales, excess stock, and unhappy customers.

Retano SCM is an AI-driven solution that brings clarity and control—automating critical processes, minimizing human effort, and unlocking higher efficiency across the board.

Key Highlights

Retano SCM is a SaaS-based solution leveraging BigData&AI for automated supply chain management in retail.

Suitable for retailers of any size, format, and product range seeking rapid improvement in supply chain quality.

Quick Launch. Fast Results.

Deployed in 3-6 months — with measurable business impact from the very first weeks.

No additional hardware or server infrastructure needed.

Compatible with any ERP solution used by retailers.

Seamless integration without requiring changes to merchandising, store management systems, or WMS.

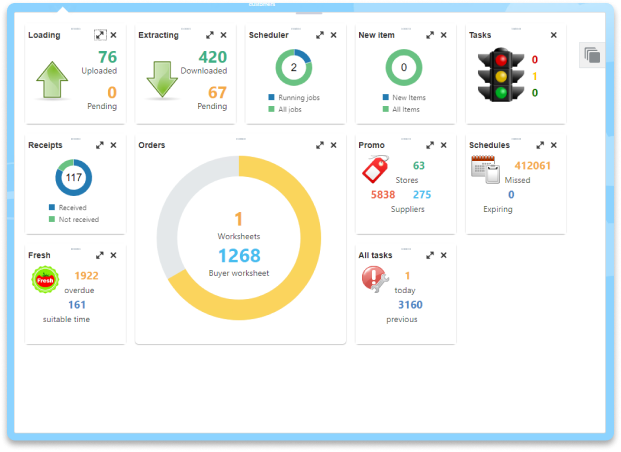

Manual intervention is only necessary for exceptions.

What’s more, the system pinpoints the precise areas requiring attention.

Smarter than auto-replenishment:

AI-driven accuracy, end to end.

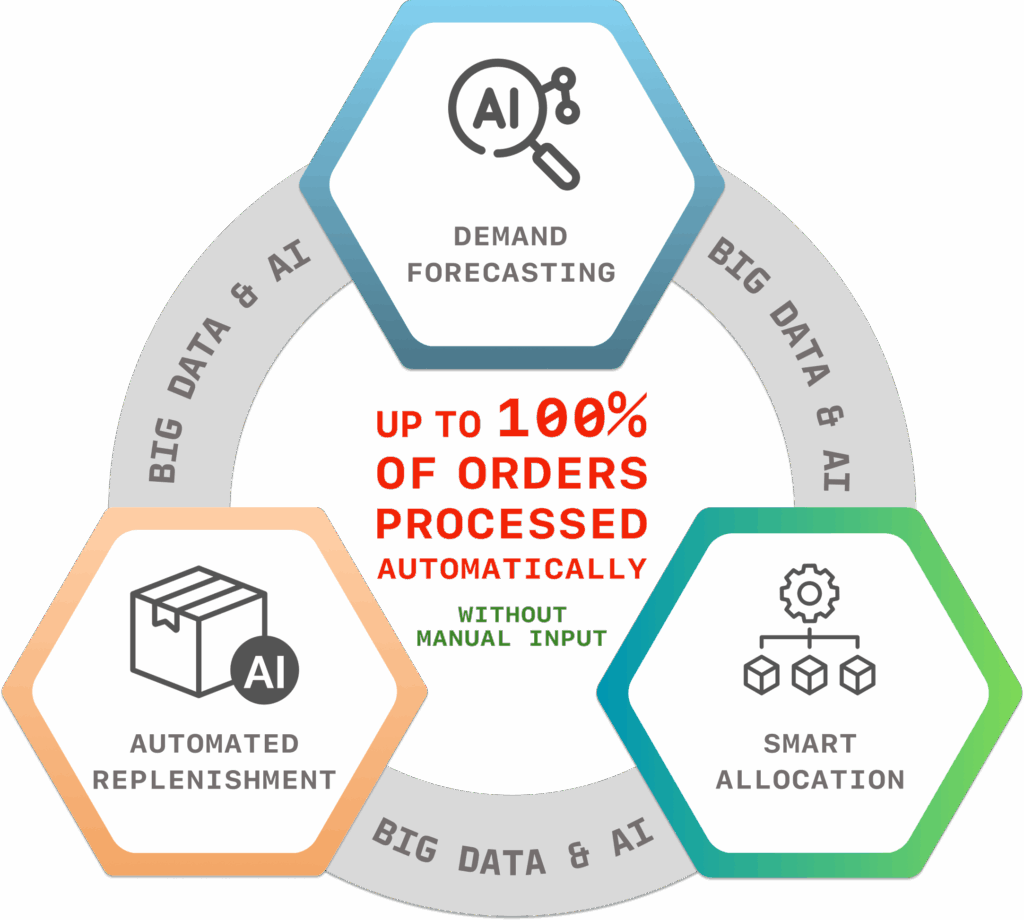

Retano SCM handles the entire inventory management process — from deep data analysis and demand forecasting to generating and approving orders.

The system independently and automatically, every day:

- Cleans and analyzes sales and inventory data.

- Forecasts demand with consideration for seasonality, promotions, trends, and customer behavior.

- Calculates the optimal order quantity for each item.

- Adjusts orders based on actual stock levels and expiration dates.

- Generates ready-to-approve orders — either manually by a manager or automatically on schedule.

Our system calculates replenishment quantities based on sales forecasts, demand variability, and takes into account all relevant supply chain constraints. This ensures efficient inventory management while reducing the need for manual intervention.

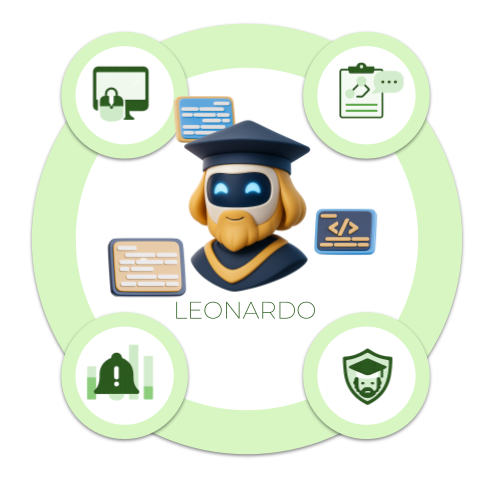

Leonardo, built-in AI Assistant, turns complex data into clear, reasoned actions

Our virtual assistant is designed to transform complex supply chain tasks into transparent, repeatable, and high-quality decisions.

This powerful AI tool automatically explains how an order was calculated, clearly shows why a specific quantity was formed. It highlights key factors and risks, making the entire calculation process transparent for the employee.

Benefits for your Team:

- Prioritized Focus: The assistant generates a daily alert summary, pinpoints the most critical issues, and helps your team quickly determine priorities.

- Reduced Workload: By automating analytical breakdowns and providing instant rationale, the assistant supports the main SCM operational scenarios and significantly reduces the workload on the team.

Challenges Addressed by Retano SCM

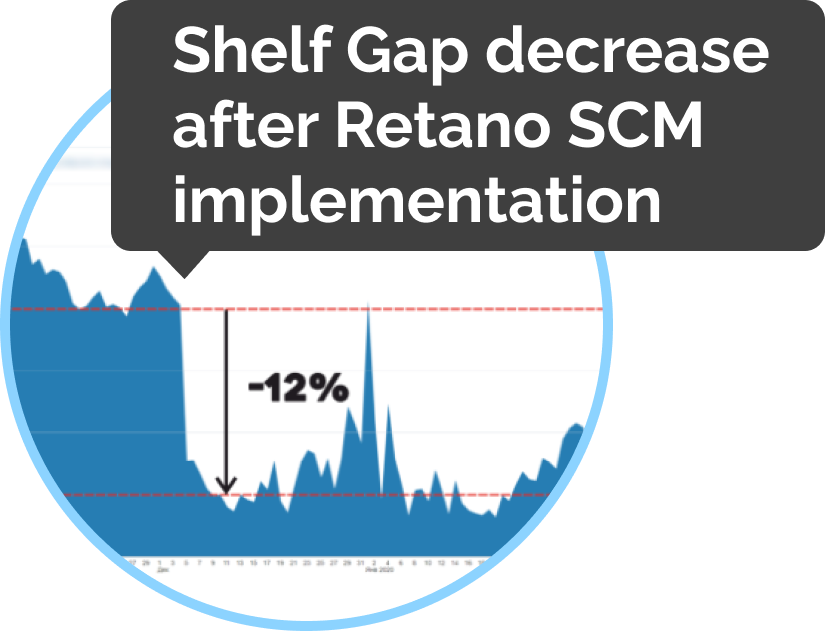

Optimal Product Availability in Stores

Introduce commercially valuable products into your range and mitigate the issue of inconsistent product availability on shelves. This inconsistency often results in lost sales and reduced replenishment volumes, particularly for products with limited shelf life. Without intervention, this pattern can lead to the gradual disappearance of these products from the range altogether. By implementing Retano SCM, you can effectively reduce lost sales by addressing product availability issues and maintaining a consistent supply on store shelves.

The impact of customers not finding products on shelves cannot be underestimated, as it may result in irreversible loss of customers to competitors. This damage can be significant for retailers. Retano SCM is specifically designed to prevent such scenarios by ensuring consistent product availability, thereby retaining customers and mitigating the risk of customer attrition to competitors.

Stock optimization

In typical scenarios, payment delays to suppliers do not exceed the time required to sell the products they provide. However, if the sales cycle is prolonged, it results in capital being tied up in inventory, negatively impacting the retailer’s performance. By improving the quality of supply chain processes, it becomes possible to release this tied-up capital and enhance overall performance.

The proportion of waste is directly related to the size of the inventory. As the inventory decreases, the percentage of waste also decreases. Accurate forecasting plays a crucial role in minimizing waste losses, as it enables better inventory management and reduces the risk of overstocking.

Decrease in logistics costs

Achieve optimal inventory replenishment for distribution centers (DCs) and stores through Retano SCM.

Our system’s order calculation process considers critical logistical parameters including lead time, pack size, expiration dates, and order submission time limits.

By accurately calculating orders, retailers can implement efficient cargo management processes such as cross-docking and pick-by-line for storage and DC operations. Notably, renowned retailers like Tesco utilize these mechanisms to drive operational excellence.

Less manual corrections and labor

Retano SCM provides the ability to compare key performance indicators (KPIs) of the supply chain between automated and manual ordering processes, enhancing decision-making transparency.

By utilizing Retano SCM, retailers can reduce their reliance on the human factor. While experienced employees are capable of creating high-quality orders, the performance of AI-driven systems surpasses human capabilities over time, minimizing errors. Additionally, the solution mitigates the challenge of knowledge transfer for new personnel, ensuring consistent and optimal performance regardless of expertise level.

Retano SCM features

Forecasting based on demand, not sales

- Retano SCM excels in providing accurate demand forecasts by leveraging clean sales statistics. It takes into account various factors such as out-of-stock situations, sales anomalies, promotional activities, seasonal variations, and holidays.

- Retano SCM is based on advanced mathematical forecasting methods, proven effective and trusted by leading retailers for accurate demand prediction. They possess the capability to detect trends and seasonality patterns, even for products with infrequent sales or limited sales history based on aggregated data at different hierarchy levels.

Automatically selects best forecasts to reduce manual work

Artificial Intelligence for Maximum Efficiency

AI that guides your decisions — visually, clearly, confidently.

At the core of Retano SCM are machine learning and intelligent analysis technologies, specifically adapted for retail’s practical challenges. These are powerful and highly effective AI algorithms that:

- Continuously learn from your data and improve prediction accuracy over time.

- Apply different approaches depending on the sales channel: stores, e-commerce, wholesale, and marketplaces.

- Automatically select analogues for new products, even if the item has no sales history yet.

- Forecast promotional orders, considering discount depth, display location, and seasonal factors.

Ready to discover how Retano SCM can optimize your supply chain, reduce out-of-stock situations, minimize lost sales, free up working capital, and accelerate your growth? Request a demo today!

FAQ

Publications

Anvar boosts Customer Engagement with enhanced Retano CRM & Loyalty Platform

Key Benefits of the new platform: Modern and Reliable Technology The new platform is built on a high-performance microservices architecture, ensuring that Anvar’s loyalty system remains fast and reliable as the chain continues to grow. The transition to an event-driven model allows for near-instant transaction processing and improved security through JWT token authentication. This upgrade… Read More »Anvar boosts Customer Engagement with enhanced Retano CRM & Loyalty Platform

Brico Io ready for the Retano Shelf Space rollout

Brico io, an Italian DIY retailer owned by Coop Lombardia group, has reached the final stage of implementing Retano Shelf Space, solution for the automated management of store space. Agostino RUSSO,Chief Information OfficerBrico Io “The project with Retano comes from the evolution of our Space Management process with a dynamic and integrated model. In Retano Shelf Space we… Read More »Brico Io ready for the Retano Shelf Space rollout

Azbuka implements Retano SCM for replenishment planning

Azbuka, one of the leading grocery retailers in Kyrgyzstan operating supermarkets and convenience stores, has launched the implementation of the SaaS-based Retano SCM platform to support centralized supply chain management. Retano SCM is a cloud-native system that uses historical sales and inventory data to support demand forecasting and replenishment decisions. Forecast accuracy improves over time… Read More »Azbuka implements Retano SCM for replenishment planning